Welcome to our Company

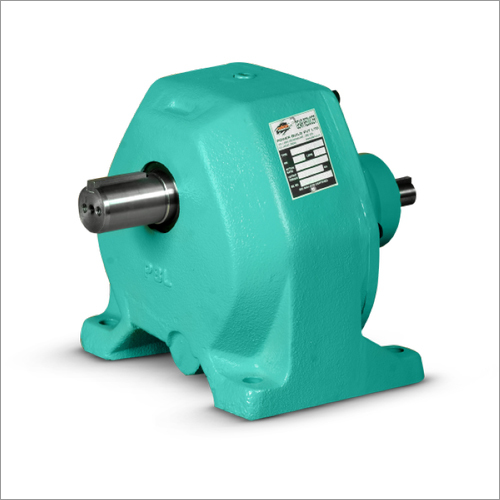

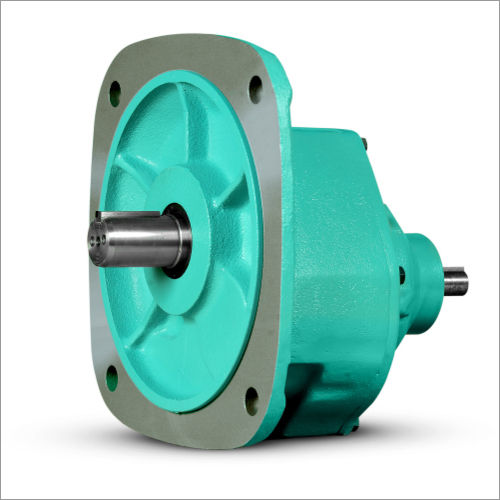

PBL 3 Phase Helical Gear Box

8000.00 INR/Unit

Product Details:

- Usage Industrial

- Gear Type Worm Gears

- Material Stainless Steel

- Processing Type Machined

- Gear Tooth Profile Helical

- Product Type PBL 3 Phase Helical Gear Box

- Gearing Arrangement Parallel shaft

- Click to View more

X

PBL 3 Phase Helical Gear Box Price And Quantity

- 20 , , Unit

- 8000.00 INR/Unit

PBL 3 Phase Helical Gear Box Product Specifications

- Up to 96%

- 1440 rpm

- Stainless Steel

- Helical

- 415 V

- Up to 200 kW

- 40 1250 rpm

- Both directions

- PBL 3 Phase Helical Gear Box

- Parallel shaft

- Worm Gears

- Green

- Machined

- Industrial

- Up to 11500 Nm

PBL 3 Phase Helical Gear Box Trade Information

- 10 Days

- All India

Product Description

Our organization is offering an assorted variety of PBL3 Phase Helical Gear Box. It canhandle more load than spur gears. Apart from this, provided box is known for its great advantage such as low weight, compact design and high torques. PBL3 Phase Helical Gear Box is less efficient because they have more teeth touching when two gears are connected. It is easy to operate and efficient to tolerate a high loading carrying capacity without any worry.

Superior Efficiency and Performance

Designed for demanding industrial use, the PBL 3 Phase Helical Gear Box delivers up to 96% efficiency, ensuring remarkable energy savings and minimized operational costs. Its precision-machined helical gears and parallel shaft arrangement provide reliable transmission of high torque, smooth power flow, and low noise levels, supporting a wide range of machinery with rated power up to 200 kW.

Durable Construction and Flexible Installation

Crafted from high-grade stainless steel, the gear box is corrosion-resistant and built for longevity. With both foot and flange mounting options, it adapts seamlessly to different setups. The IP55 protection class shields the unit from dust and water ingress, guaranteeing dependable performance in tough industrial environments.

FAQ's of PBL 3 Phase Helical Gear Box:

Q: How is the PBL 3 Phase Helical Gear Box typically installed?

A: Installation is flexible-users can choose either foot or flange mounting types, making it compatible with various industrial configurations. Detailed mounting instructions are included with the unit to ensure proper alignment and secure setup.Q: What cooling methods are available and when should I use them?

A: The gear box supports both natural and forced cooling. Natural cooling works well for standard loads and ambient conditions, while forced cooling is recommended when operating continuously at high power or in hot environments to maintain optimal performance.Q: Where can the PBL Helical Gear Box be used?

A: This gearbox is ideal for a variety of industrial applications, such as conveyors, mixers, and heavy machinery. Its robust design and high output torque make it suitable for demanding processes in manufacturing plants, power stations, and processing industries across India.Q: What are the benefits of its helical gear tooth profile and parallel shaft arrangement?

A: Helical gear tooth profiles provide smoother, quieter operation and greater load-carrying capacity than straight teeth. The parallel shaft arrangement ensures efficient torque transfer and more compact machinery layouts.Q: How does the lubrication system work, and which option should I select?

A: The gear box offers splash and pump circulation lubrication. Splash lubrication is suitable for moderate speeds and loads, while pump circulation is ideal for demanding applications that require consistent oil flow and cooling to ensure longer gear life.Q: What protections does the IP55 rating provide?

A: IP55 protection safeguards the gearbox against limited dust ingress and water jets from any direction. This ensures reliability and durability, even in environments with exposure to dust or occasional water splash.Q: What is the efficiency of the gear box and why is it important?

A: With efficiency up to 96%, the gear box minimizes energy loss, reducing operational costs and environmental impact. High efficiency also means less heat generation, supporting longer service intervals and dependable performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email